From technical CAD files to multi-language marketing collateral, today’s manufacturers are producing more digital content than ever before. But with dispersed teams, varied file formats, and high compliance stakes, managing it all without a central system leads to delays, errors, and inefficiencies. DAM for manufacturing organizations can massively improve content operations.

As a centralized platform for organizing, distributing, and securing digital assets, DAM is transforming how manufacturers work—improving collaboration, accelerating time-to-market, and ensuring brand and regulatory consistency across every channel.

What is Digital Asset Management (DAM) in Manufacturing?

Digital Asset Management (DAM) is a cloud-based system for storing, organizing, sharing, and tracking digital files—everything from images and videos to technical documents and CAD renderings.

For manufacturers, a DAM system becomes the single source of truth for internal teams, global distributors, marketing agencies, and sales partners—ensuring everyone accesses the most up-to-date, approved content, no matter where they are.

Common Manufacturing Content Challenges

Manufacturing organizations generate and distribute massive volumes of digital content across departments, regions, and partner networks. But without a centralized system like a DAM, teams often encounter critical inefficiencies that slow down operations and introduce risk.

1. Disorganized Libraries and Scattered Storage

Manufacturing teams frequently rely on shared drives, email attachments, or legacy servers to store and access digital assets. As a result, content ends up scattered across folders, platforms, and even personal desktops. Searching for a specific image, product sheet, or CAD file becomes time-consuming—especially when you need the latest version fast.

- Repetitive tasks like recreating lost files waste hours of productivity.

- Version confusion leads to outdated specs being shared with customers or distributors.

- Teams working across departments (engineering, sales, marketing) often lack visibility into what content already exists.

2. Outdated or Inconsistent Brand Assets

As brands evolve—updating logos, color palettes, or messaging—manufacturing teams must ensure every distributor and regional office uses the most current brand-approved content. Without controls in place, old assets continue circulating, leading to:

- Off-brand materials in local markets

- Confusing experiences for customers and partners

- Lost time correcting incorrect or unauthorized usage

This inconsistency is especially damaging when launching new products, entering new markets, or managing multi-lingual campaigns.

3. Compliance and Regulatory Risk

Manufacturers in industries like aerospace, medical devices, energy, and industrial tools must comply with strict regulations. If outdated safety documentation or incorrect product specs are shared, the consequences can be serious:

- Fines, delays, or product recalls

- Legal exposure from incorrect usage claims

- Loss of trust with partners and customers

Without audit trails, expiry notifications, or access controls, teams can’t confidently manage which documents are still valid—or who has downloaded what.

4. Bottlenecks in Asset Requests and Approvals

In many organizations, requests for product images, installation manuals, or localized marketing materials are handled manually—via email or Slack. This creates major workflow bottlenecks, especially when:

- The marketing team is small and stretched thin

- Regional offices are in different time zones

- Urgent sales opportunities arise and content isn’t immediately available

Instead of focusing on strategy, teams spend hours fulfilling routine requests—slowing down launches and straining internal resources.

5. Complex File Formats and Access Issues

Manufacturers rely heavily on AutoCAD, SolidWorks, 3D files, and other large technical formats that traditional storage tools struggle to manage. Without a DAM:

- Stakeholders need native software to preview or open these files

- File sharing becomes risky or impossible due to size limits or format restrictions

- Non-technical users (e.g., marketing or sales) can’t engage with assets they need to approve or distribute

This slows down collaboration and can stall product content workflows.

6. Siloed Systems and Disconnected Teams

With so many departments involved in product development, sales enablement, and marketing, teams often operate in disconnected systems—PIMs, CRMs, CMSs, design tools—with no shared visibility into digital assets.

- Assets may exist in multiple formats or platforms with no clear owner

- Collaboration between creative, engineering, and marketing becomes fractured

- Global teams can’t find or trust the assets available to them

This siloed structure stifles innovation, delays go-to-market efforts, and increases content duplication.

Key Benefits of DAM for Manufacturing

1. Centralized, Searchable Asset Access

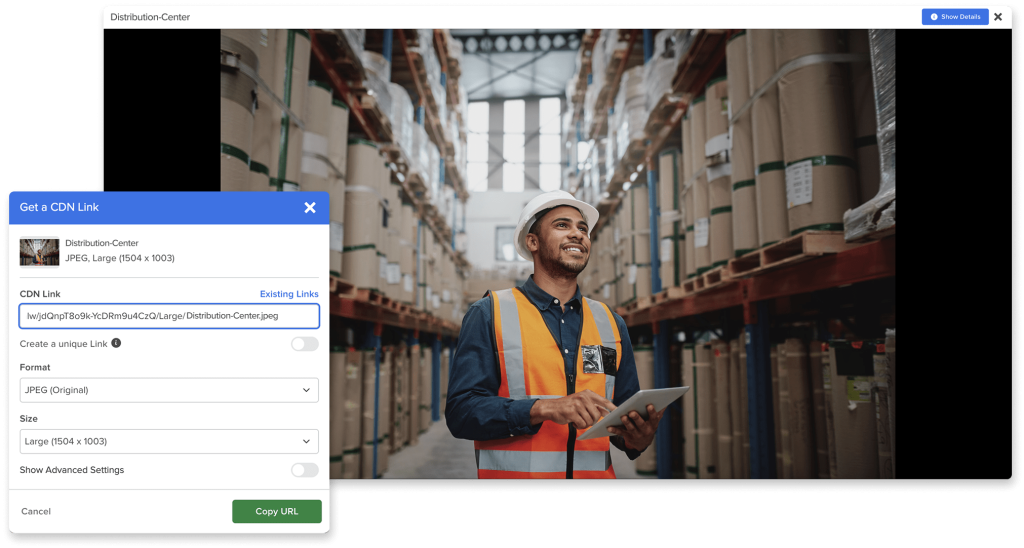

Manufacturers manage thousands of assets: product imagery, videos, installation guides, CAD files, safety data sheets, and more. DAM centralizes these files with structured metadata and AI-powered search, reducing time spent hunting for the right version.

2. Support for Technical Files, Including AutoCAD and 3D Formats

Unlike traditional storage systems, MediaValet’s DAM supports AutoCAD (.dwg), 3D models, and other large-format technical files, enabling engineering, product, and marketing teams to preview, collaborate on, and share these files without requiring native software access. Stakeholders can view and approve renderings directly in the browser—reducing friction and maintaining version control.

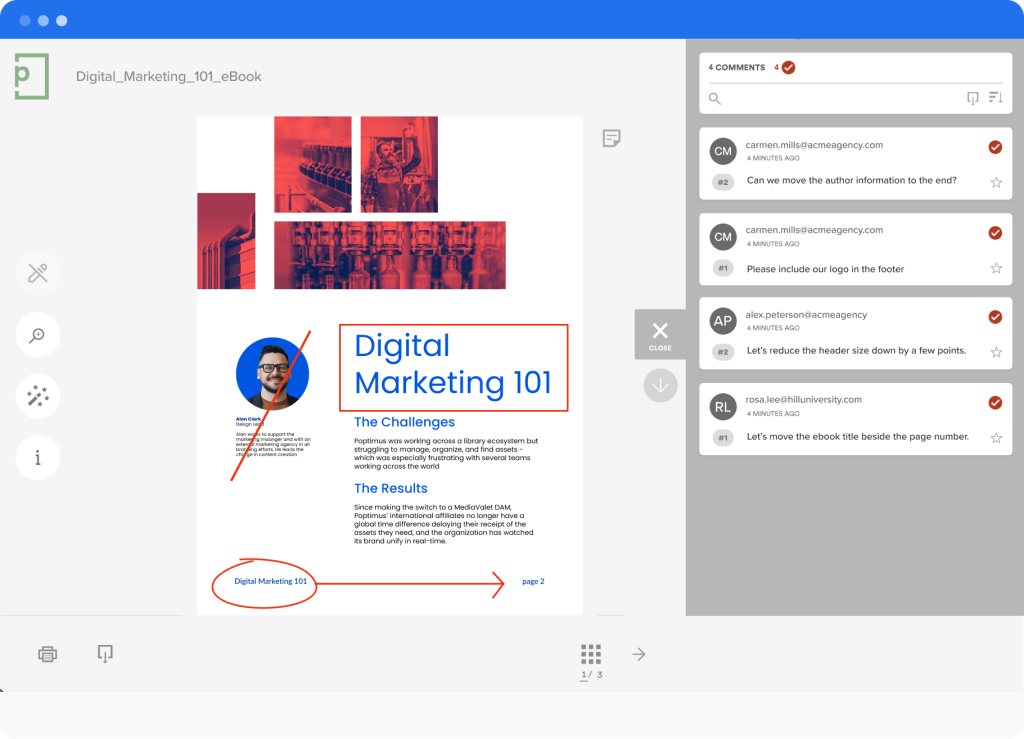

3. Streamlined Workflows Across Departments

DAM connects teams across marketing, engineering, product, and sales with built-in versioning, approvals, and integrations with tools like Adobe Creative Cloud, PIM, and CMS platforms. For manufacturing orgs launching global product lines or updating product specs frequently, this alignment is critical.

4. Secure, Compliant Asset Management

With granular permissions, expiration rules, and audit trails, DAM helps manufacturers meet compliance requirements, avoid content misuse, and protect intellectual property—essential in highly regulated or IP-sensitive industries.

5. Faster Product Launches and Market Expansion

Whether launching in new regions or scaling a product line, DAM accelerates timelines by giving global teams access to localized, approved assets with consistent branding—ready to drop into campaigns, catalogs, or distributor portals.

DAM for Manufacturing Success Stories

Enabling Global Self-Service with DAM

As a world leader in environmental and industrial measurement, Vaisala needed a way to support internal teams and over 700 distributors worldwide with on-brand, up-to-date content.

By implementing MediaValet, they created a self-service content hub for sales teams and partners to easily find, download, and share localized marketing materials, 3D renderings, and product visuals. What was once a high-volume, manual request process became a seamless self-serve experience—saving their small marketing team hours of work each week and ensuring faster regional launches.

“I used to spend 30% of my time just responding to requests for content. Now, people can access exactly what they need, when they need it.”

— Salla Ahola, Marketing Communications Specialist, VaisalaRead the full Vaisala use case here.

Powering Global Growth with Scalable DAM

HYTORC, a global manufacturer of industrial bolting systems, needed a scalable way to manage product images, training videos, and manuals in multiple languages. Before DAM, asset requests piled up in email chains, and content was stored in disconnected systems.

With MediaValet, they created a centralized library with structured categories by product, region, and language—allowing international distributors and employees to quickly locate content. They now support rapid expansion into new markets with confidence, thanks to consistent branding and faster approvals.

“The ability to organize by language, product line, and country has made it easier for our global teams to serve customers.”

— Dave Maher, Global Marketing Manager, HYTORC

Best Practices for Implementing a Manufacturing DAM

Successfully implementing a Digital Asset Management system isn’t just about purchasing the right tool—it’s about aligning teams, processes, and goals to ensure adoption and long-term success. Below are key best practices manufacturing organizations should follow when introducing a DAM platform:

1. Audit Your Current Asset Ecosystem

Before implementing DAM, conduct a comprehensive asset audit to understand what content you already have, where it lives, and how it’s being used. This process helps set a baseline for migration and highlights opportunities to improve structure and governance.

2. Engage Stakeholders Early Across Departments

DAM isn’t just a marketing initiative—it affects engineering, product, legal, IT, sales, and international partners. Include representatives from each key department in planning conversations. In manufacturing especially, cross-functional alignment is critical to success due to the diverse use cases and file types involved.

3. Design a Scalable Folder Structure and Metadata Strategy

Your folder structure and tagging system will determine how easy it is for users to find what they need. This not only improves discoverability but lays the foundation for automation, personalization, and AI-driven asset recommendations.

4. Ensure Compatibility with CAD, 3D, and Technical Files

Manufacturing content isn’t limited to JPEGs and PDFs. Your DAM needs to support complex file types.

This ensures your DAM can serve both technical and non-technical users across the organization.

5. Integrate with Core Tools and Platforms

A DAM that operates in isolation won’t deliver full value. Integrate with the tools your teams already use. Integrations reduce manual effort, speed up collaboration, and ensure content flows where it’s needed.

6. Establish Governance, Permissions, and Workflows

Set clear guidelines to ensure users access the right assets, at the right time, with the right permissions.

Strong governance reduces risk, supports compliance, and protects intellectual property.

7. Train, Launch, and Drive Adoption Strategically

A successful DAM rollout requires planning beyond implementation:

8. Monitor Performance and Optimize Over Time

Once launched, treat your DAM like a living system:

Want to see a MediaValet DAM in action? Take the self-guided tour here!

DAM: A Smarter Way to Manage Manufacturing Content

DAM isn’t just a marketing tool—it’s an operational advantage. For manufacturers, it’s the key to navigating growing content demands, increasing market speed, and protecting brand integrity.

From AutoCAD files to training videos, DAM ensures that the right content is in the right hands—every time.

Related Articles

Join our family of happy customers

Book a demo with one of our product experts.